Authorized Canadian Dealer & Distributor

When space is limited.

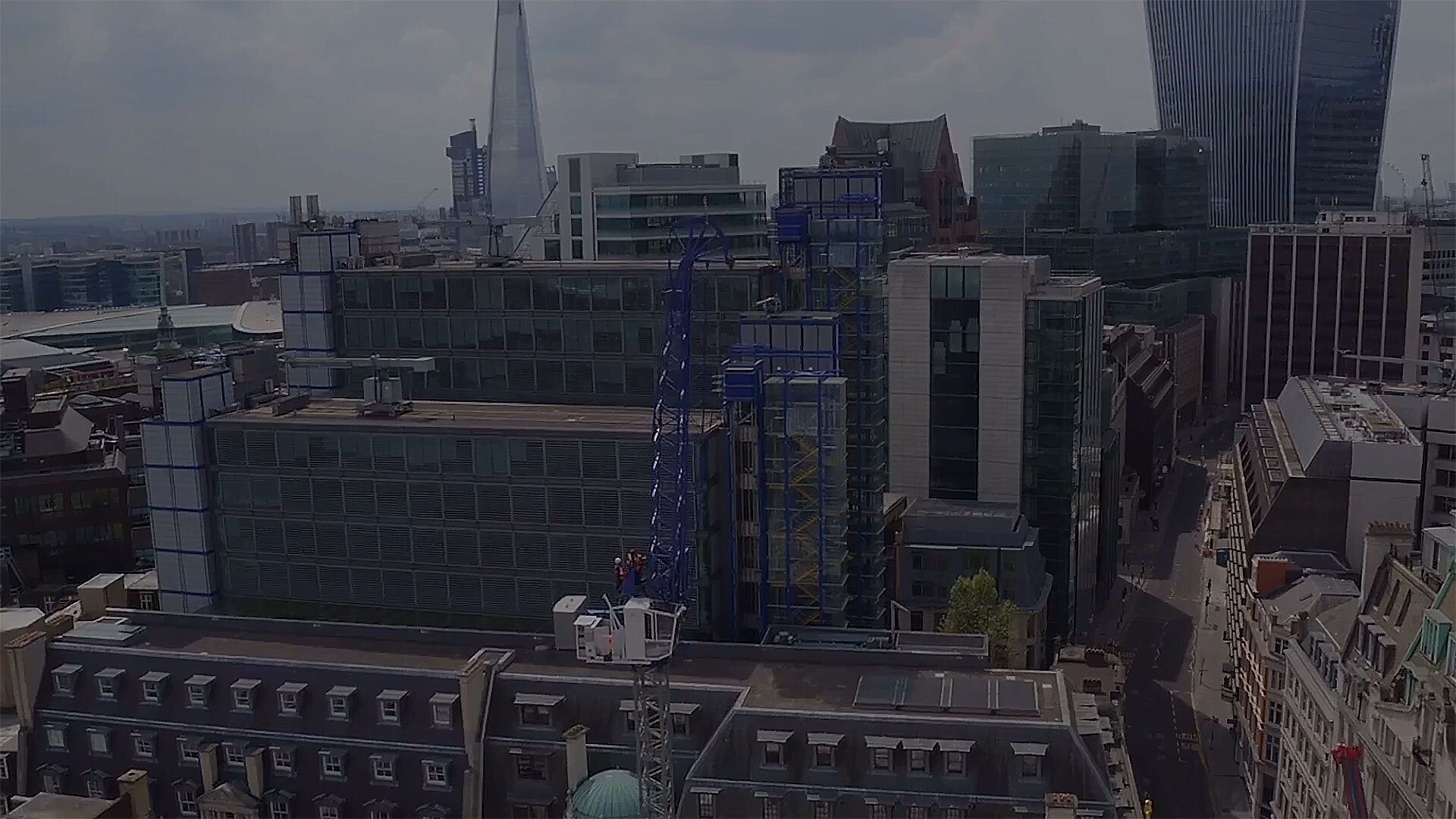

The Raptor crane series is developed and built for accurate lifting and high working speed, especially in confined inner city sites and where air space regulations are a major issue. Its unsurpassed out-of-service radius is a phenomenal feature in narrow spaces.

The first Raptor 84 came out on the market in 2010, and its big brother Raptor 184 in 2017.

Designed according to EN 14439. Made in Sweden. Always.

Raptor 48

The Raptor 48 is our smallest crane with our famous articulated jib. It has a maximum load of 3 tonnes at a 17.5 metres radius, and its low weight makes it ideal for refurbishment projects.

Raptor 84

The Raptor 84 first came out in 2010, and has become the industry standard when it comes to cranes for restricted areas with airspace issues. It has a maximum load of 4 tonnes at 21 metres radius, and with a maximum tower height of 100 metres.

Raptor 184

The Raptor 184 from 2017 is our largest crane yet. With a maximum load of 8 tonnes at 22.5 metres radius, and a tower height of up to 150 metres, you’ll have a real powerhouse for your building project.

RAPTOR 48 - TECH SPECS

| Hoisting speed 0→3 tonnes Max hook height |

81→0 m/min 150 metres |

|

| Luffing speed | 0→45 m/min | |

| Slewing speed | 0→1.3 rpm | |

| Safe working load | Max load 3 tonnes @ 17.5 metres Max load 1.4 tonnes @ 30.0 metres |

|

| Min out-of-service radius | 4.6 metres | |

| Free standing lifting height | 30 metres on standard 1.2 m tower (other towers are available) | |

| Hoisting motor power Luffing motor power Slewing motor power |

22 kW 15 kW 5.5 kW |

|

| Power supply Power consumption |

400–480 V 50/60 Hz 55 kVA |

|

| Main fuses | 80 A (400 V, 50 Hz) | |

RAPTOR 84 - TECH SPECS

| Hoisting speed 0→4 tonnes Hoisting rope length |

100→45 m/min 235 m |

|

| Luffing speed Luffing rope length |

0→40 m/min 53 m |

|

| Slewing speed | 0→1.3 rpm | |

| Safe working load | Max load 4 tonnes @ 21 metres Max load 2 tonnes @ 32 metres |

|

| Min out-of-service radius | 4 metres | |

| Free standing lifting height | 32 metres on standard 1.2 m tower (other towers are available) |

|

| Hoisting motor power Luffing motor power Slewing motor power |

30 kW 15 kW 5.5 kW |

|

| Power supply Power consumption |

400–480 V 50/60 Hz 75 kVA |

|

| Main fuses | 100 A (400 V, 50 Hz) | |

RAPTOR 184 - TECH SPECS

| Hoisting speed 0→8 tonnes Hoisting rope length |

95→40 m/min 235 m |

|

| Luffing speed Luffing rope length |

0→45 m/min 60 m |

|

| Slewing speed | 0→1.3 rpm | |

| Safe working load | Max load 8 tonnes @ 23 metres Max load 4 tonnes @ 36 metres |

|

| Min out-of-service radius | 4.5 metres | |

| Free standing lifting height | 42 metres on standard 1.7 m tower (other towers are available) |

|

| Hoisting motor power Luffing motor power Slewing motor power |

60 kW 22 kW 7.5 kW |

|

| Power supply Power consumption |

400–480 V 50/60 Hz 115 kVA |

|

| Main fuses | 150 A (400 V, 50 Hz) | |

iRaptor can save lives

The iRaptor from Artic Crane, together with a rescue basket stretcher, uniforms a safe and compact driver rescue system – DRS. The DRS system solves the problem to get a crane driver down on ground in case of heart problem or other severe illness. The iRaptor is strong, speedy and safe which is crucial in an emergency situation.

The hook movement is controlled by a frequency inverter which gives a safe, smooth emergency ride to the patient. If a power failure appears during a rescue situation, the battery back-up makes it possible to continuing the descending process of the patient. iRaptor is also equipped with a top-run over switch and an overload system.

Safety and comfort

With the operator’s best in mind

The large cab windows give the crane operator full visibility of the load and work area at all times. The seat is comfortable and ergonomically adjustable to maximize the operator’s day-to-day performance and well-being. The cab includes heated seat, a touch screen display system, heater, ventilation fan, LED lighting, bottle holder among other smart solutions.

Fail-safe system

If a failure of some reason appears in the inverter drives, the load control system will detect and stop the luffing and/or the hoist motion, before any dangerous situation appears. This safety system helps the operator to stop the descending load in a fraction of a second.

12 True Benefits with the

Slack Rope Detection

The luffing machinery is equipped with a slack rope detection and stopping system.

5. Safe Environment

The back jib slewing part and cab all have the same floor level for easy access. The solid aluminum floor prevents small parts and tools falling from the crane.

2. Display System

All drives on board are controlled by PLC and inverter technology. For extra safety, the electrical cabinet and the driver’s cab are fitted in different compartments.

4. PLC controlled

The back jib slewing part and cab all have the same floor level for easy access. The solid aluminum floor prevents small parts and tools falling from the crane.

3. Short Counter Jib

A extremely short out-of-service radius, means the crane can fit into very tight building sites without over-sailing adjacent properties.

6. Motors & Gearboxes

The electric powered heavy-duty motors and gearboxes are manufactured by SEW Eurodrive to the special needs of crane operation.

7. Safe climbing

Our ladders are safe and have the perfect angle for a comfortable climb, and the rest platforms are as big as they can be and has generous toe boards.

10. Automatic lubrication

The automatic lubrication system along with bushings of solid bronze ensure a long service life.

8. Absolute levelling

Our unique shape of the crest levels the hook path over the full working radius, making the crane a pleasure to operate.

11. Steel shelves

We have developed and manufactured our own steel sheaves for a long and trouble free lift time of the wire ropes.

9. High quality parts

We only use high quality parts and steel from Europe. Each single component is chosen by us with respect to function, quality and safety.

12. Double-secured tower sections

We believe that the best tower sections are pinned together with two pins in each corner. Each pin connection must be reinforced with steel plates made of Weldox steel to ensure a long service life without wear and tear. All parts inside the tower are hot dip galvanized. Pins have a storage place on the platform and they can be removed from the tower with a hydraulic puller if necessary.

Easy transportation – fast mounting

Transport and erection

Each 12 metres tower section is transported on one trailer. The A-frame, slewing part and a 6 metres tower section arrives on one trailer, and the cab aerial counterweights and operator’s cab on one trailer.

The whole jib can be transported in one piece with the hoist rope and hook block installed. The complete jib is simply lifted from the transport and fitted to the crane.

On site

The crane can stand on a concrete foundation, a base cross or be internally climbed through a building to give up to 150 metres lifting height on three hoist rope layers.

The crane can easily be erected and put into service in just one day. The erectors only need a hammer and two spanners.

The Raptor cranes are also ideal for working in close proximity to luffer cranes or other Raptors with minimal interference. Our cranes are easy to connect with any anti-collision system.

About Artic Crane

Artic Crane, founded in 2007, is a Swedish company specializing in the design and manufacturing of articulated tower cranes.

In Sweden, they have a long tradition of developing high quality building machines, a tradition that the management team of Artic Crane have in their blood. They have inherited this knowledge and carefully developed it together with the latest technology and merged it into the articulated tower crane Raptor 84 and Raptor 184.

The result is an amazing tower crane with high working speed, accurate lifting and operator friendly control, in the safest way possible. Safety is always the primary concern when it comes to a Raptor crane.